- Accepts standard sign paints, inks and vinyl graphics.

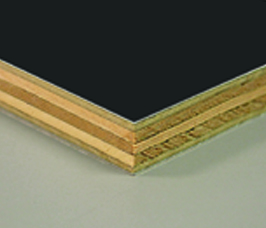

- Substrate provides structural strength for demanding project requirements.

- Available in single or double-sided.

- High-density polyethylene (HDPE) backer available on single-sided product.

-

UL - Listed on double-sided product.

Standard

Sizes

4' x 8'

4' x 10'

Fire-Rating

Class A*

Nominal

Thickness

Plywood

.500 "

*Double-sided only

Painted Colors

Notes: Colors are a glossy finish. Panel colors within this website are RGB equivalent. For the best color representation contact your PRIME PANELS representative for a product sample.

2-year limited warranty*

*Note: Warranty may be voided if panel is not sealed per the Wood Core Sealant Instructions listed on this web page.

Prime Panels Sign Panel Important Installation Notice

Prior to exterior installation of Aluminum Faced Plywood Panels, all exposed sign panel edges and fastening holes must be sealed

properly to prevent moisture from penetrating substrate. Failure to properly seal panel edges as detailed in this Installation

Notice will cause panel deterioration and negate panel warranty. Edge sealing of a wood substrate panel is required and critical

to long term product performance in exterior installations.

Required method for sealing exposed Aluminum Faced Plywood Panel edges for exterior applications

Prime Panels Vinyl or Aluminum Cap Method with 100% Silicone Sealant

-

Remove protective film.

- Notch or miter Prime Panels cap to align with corner.

- Place a bead of 100% silicone sealant along length of Prime Panels cap, applying sufficient amount to have a slight squeeze

out on both sides of cap. Wipe away any excess immediately with clean dry cloth.

- Apply Prime Panels cap to edge of board starting at corner and working outward.

Note: Prime Panels Vinyl and Aluminum Caps are not recommended for curved edges. For curved edges use a flexible molding and follow the steps above.

If either Prime Panels moldings or flexible moldings fail to cover the edges at any time during warranty period,

the warranty will be voided. Use Prime Panels Vinyl cap and silicone sealant whenever possible.

Failure to use Prime Panels Vinyl Cap and 100% silicone sealant on "straight" sign edges will void panel warranty.

Check with your local distributor and ensure your cap is Prime Panels brand. Be sure the sealant is 100% silicone sealant.

Fill all fastener holes with silicone

- Fill all holes with 100% silicone sealant before fastening screws.

- Secure fastener and wipe away any excess silicone sealant.

- Use oversize fastener heads or washers to allow for thermal expansion and contraction of panel.